Choosing the right processor architecture for an industrial single-board computer (SBC) is one of the most important technical and business decisions in any embedded project. The choice between ARM and x86 is not just about processor speed—it affects everything from thermal design and power budgets to software development, maintenance, and long-term supply. In industrial environments, where products may need to operate continuously for a decade or more, the architecture you choose will directly influence system reliability, development costs, and your ability to adapt to future requirements.

Understanding ARM and x86 Architectures

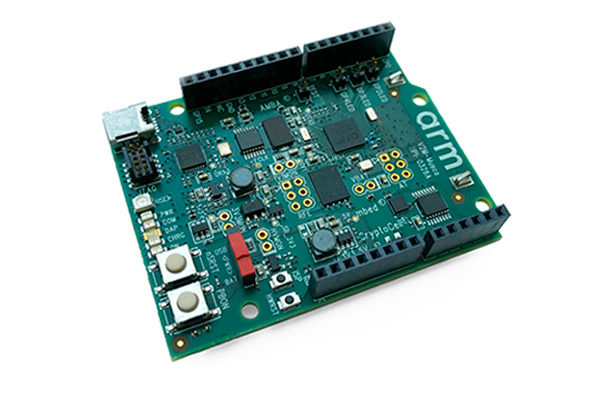

ARM processors are built on the Reduced Instruction Set Computing (RISC) philosophy, which uses a simplified set of instructions to execute tasks efficiently. This design approach allows ARM processors to achieve high performance per watt, making them ideal for low-power, compact, and thermally constrained systems. They dominate the mobile and embedded world, from smartphones to IoT devices, and have gained significant ground in industrial automation, medical equipment, and smart infrastructure.

x86 processors, on the other hand, follow the Complex Instruction Set Computing (CISC) model. Popularized by Intel and AMD, this architecture offers a broad and mature software ecosystem, robust backward compatibility with older applications, and exceptional performance in computationally demanding workloads. While x86 processors have historically been associated with desktop PCs and servers, their embedded-grade variants—such as the Intel Atom x7000E series or AMD Ryzen Embedded V2000—are purpose-built for industrial deployments, offering extended availability and specialized I/O support.

Performance and Power Efficiency in Industrial Contexts

Performance in industrial SBCs must be considered alongside thermal and power budgets. ARM-based SBCs excel in applications where power efficiency is paramount. A modern industrial ARM SoC like the Rockchip RK3568, NXP i.MX8M Plus, or TI AM62x can deliver smooth multitasking, hardware-accelerated graphics, and AI capabilities, all while consuming under 10 watts. This efficiency enables fanless operation, reducing both noise and maintenance requirements, and making these boards perfect for control cabinets, kiosk systems, or battery-powered devices.

In contrast, x86 SBCs—particularly those with multi-core Intel Core or AMD Ryzen CPUs—deliver significantly higher raw computational performance. This makes them a better fit for machine vision, real-time data analysis, and industrial AI inference. However, this performance often comes with a higher thermal output, necessitating active cooling or advanced passive heat dissipation methods. In environments where dust, vibration, or noise is a concern, the extra cooling requirements can become a design limitation.

From a performance-per-watt perspective, ARM wins decisively for continuous-operation, low-load scenarios. But if the workload is heavily threaded or requires complex calculations in real time, the higher power draw of x86 may be justified.

Software Ecosystem and Development Flexibility

The software ecosystem can be a decisive factor. ARM SBCs enjoy extensive support for Linux, Android, and various real-time operating systems (RTOS). For industrial developers, this flexibility is invaluable, allowing for lightweight, customized OS builds via tools like the Yocto Project or Buildroot. Many ARM platforms also provide integrated GPU, NPU, and multimedia acceleration blocks, reducing the need for additional hardware.

However, ARM’s dominance in embedded does not match x86’s breadth in desktop-class software compatibility. If your industrial application requires Windows 10/11 IoT Enterprise, legacy SCADA systems, or software originally developed for PC environments, x86 remains the easiest path. The vast x86 driver ecosystem also ensures better compatibility with older industrial peripherals—something that can be critical in factory modernization projects where new systems must integrate with decades-old machinery.

That said, the gap is narrowing. Many modern industrial ARM boards now support containerized workloads via Docker or Podman, meaning they can run microservices, edge AI inference, or IoT gateways with minimal friction. The deciding factor is often whether your application depends on native x86-only software.

Cost and Lifecycle Considerations

Cost in industrial computing is about far more than the unit price of the SBC. While ARM SBCs generally have a lower bill of materials (BOM) cost, their real savings often come from reduced power consumption, smaller power supplies, and simplified cooling systems. Over the lifespan of a deployment—especially one running 24/7—these operational savings can be substantial.

Lifecycle is equally critical. Many industrial ARM SoCs are produced with 10- to 15-year availability guarantees, making them ideal for long-term projects. In comparison, embedded-grade x86 CPUs from Intel and AMD typically offer 7–10 years of availability. While this still meets the needs of most industrial deployments, companies planning ultra-long product lifespans may find ARM platforms to be the safer bet.

It’s also worth noting that the global supply chain has impacted both ARM and x86 availability in recent years. However, ARM SBCs—often manufactured by a wider range of vendors—have shown slightly better resilience to shortages, particularly in mid-range models.

Application Recommendations

For low-power IoT gateways, smart HMI panels, and distributed sensor nodes, ARM SBCs are the clear choice. Their efficiency, compact form factors, and strong multimedia capabilities make them ideal for edge devices that need to operate reliably for years without maintenance. They also shine in environments where fanless operation is mandatory due to dust, noise, or vibration concerns.

For high-throughput industrial PCs, machine vision systems, and AI-assisted production line monitoring, x86 SBCs still hold the advantage. Their ability to run demanding Windows or Linux workloads, combined with multi-core CPU performance and support for large amounts of RAM, makes them the go-to choice for compute-heavy tasks.

If your industrial project also requires high-quality display integration, such as HMI panels or control terminals, then display technology plays a role as well. For example, understanding the trade-offs between IPS and OLED displays is just as important as choosing the right processor. You can explore a detailed guide here: IPS vs OLED for Embedded & Industrial Displays.

Final Thoughts

The ARM vs x86 decision for industrial SBCs ultimately comes down to application requirements, lifecycle goals, and operating environment. ARM delivers unmatched efficiency and long-term stability for embedded workloads, while x86 offers raw performance and unmatched software compatibility. In many industrial projects, the most successful designs actually combine both architectures—ARM boards at the edge for sensor data collection and preprocessing, and x86 systems at the core for analytics, visualization, and control.

Choosing wisely means considering not only what your system needs today, but also what it will need 10 years from now. And in the rapidly evolving world of industrial automation, that foresight is worth more than any single benchmark score.