Design Fanless, Reliable Industrial SBC Systems

Building a robust industrial SBC platform starts with two critical decisions: choosing the right CPU architecture and ensuring the system can operate within a sustainable thermal and power envelope. From factory automation and transportation to energy systems and remote monitoring, your hardware must remain stable in harsh environments and run 24/7 without failure.

- Fanless thermal envelopes for dust- and moisture-prone environments

- Flexible OS options: Linux, Windows IoT, and Android

- Long-term lifecycle and supply chain stability for embedded deployments

- Performance tuned for vision processing, AI inference, and HMI interfaces

- Comprehensive I/O: GbE, RS-232/422/485, CAN bus, USB, M.2, and multiple display outputs

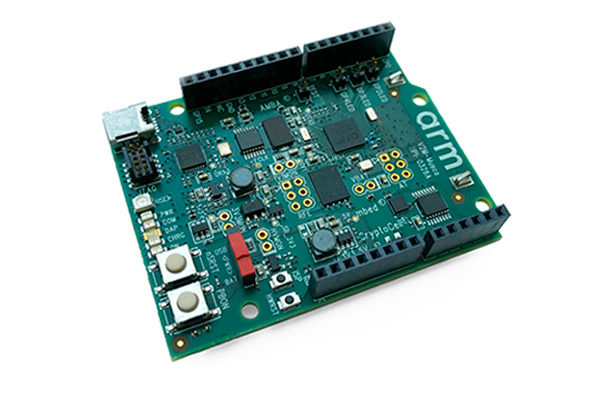

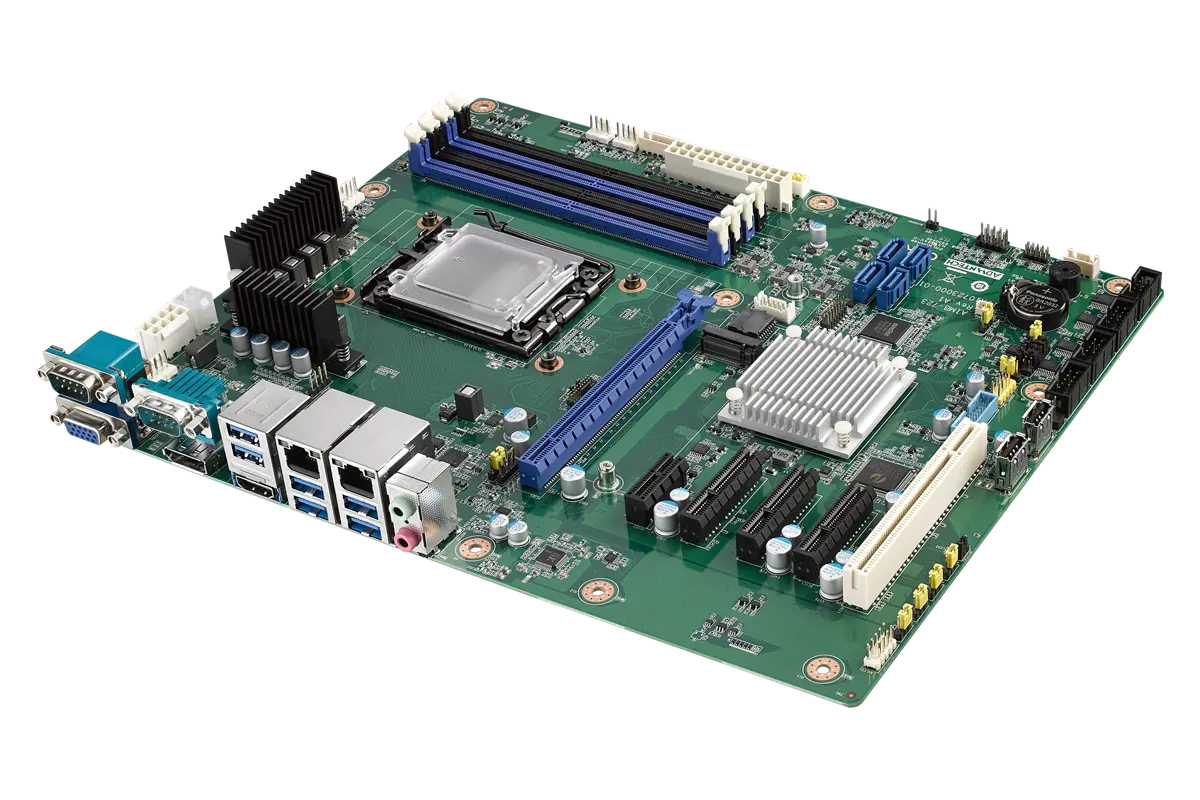

ARM vs x86

A deep dive into how each architecture performs in industrial use cases. Compare CPU efficiency, power draw, OS ecosystem, hardware longevity, and total cost of ownership to make a well-informed choice.

Read →Power Consumption

Learn how to translate workload demands into real-world wattage. Plan heatsink capacity, enclosure airflow, and PSU headroom to achieve silent, maintenance-free operation over years of service.

Read →

From Requirements to a Stable Build

Every industrial SBC project begins with a clear understanding of workload requirements—whether that's running a high-resolution operator interface, processing camera feeds for machine vision, or managing complex control logic. Once the performance target is set, validate software and driver support across the planned OS, estimate thermal output under full load, and ensure your BOM aligns with component availability for the entire product lifecycle. Only then should you lock in the board, I/O configuration, and display interface to ensure a stable and supportable system.